CRYOGENIC VALVE

Cryogenic valve are specially engineered and designed for piping systems used in the storage and transport of liquefied gasses such as LNG and liquid nitrogen and oxygen. The main structural feature of these valve is an extended bonnet with an enclosed vapor chamber to isolate packing from the cryogenic fluid and thereby allow packing to function properly. PK Vlave Cryogenic designs and liquid nitrogen testing facilities go much further to assure proven performance in this most demanding application.

Materials suitable for working condition must be adopted for low temperature VALVE. Especially in petrochemical industry, the types of fluids to be processed are different according to each section even in the same plants. At the same time, the temperatures used are also different. A full consideration must be paid to the selection of material.

As for the materials constituting the low temperature valve, special consideration must be paid to the materials used at pressure parts as in the case of body and bonnet.

TRIM:Following the body and bonnet, selection of materials for main parts such as stem, seat ring, and gland is very important. We adopt austenite stainless steel.

PACKING:Teflon or other plastic packing protecting from shinkage by large cloumn of insulating gas.http://www.didlink-valve.com

SEATING SURFACE:Stellite 6 for all medium and high pressure application prevents seizing and galling.

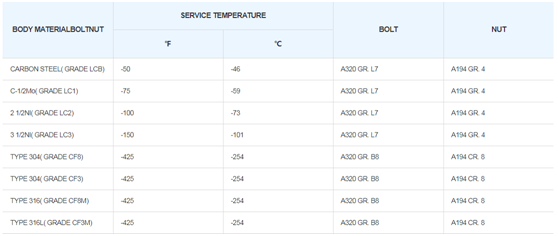

BOLT AND NUT:Material for bolts at low temperatures requires especially strength. Therefore, rigidity at low temperature is demanded and brittleness at low temperature of steel material can be improved generally by heat treatment. We use it according to ASTM standard.

JACKY

JACKY